A while ago, while repairing my old Jonsered 2050 Turbo chainsaw, I bought a Central Machinery Ultrasonic Cleaner from Harbor Freight. I heard they were really good for cleaning carburetors.

I used this thing for a while, cleaning carburetors, rusty tools, spray guns. It worked very well. Then one day I went to clean something, and it started fine, and then the liquid just stopped vibrating. I could still hear it run, but it was quieter, and there was no vibrating action.

My thought was that I would return it and get a new one, but when I checked the receipt, I had it for exactly 100 days. The warranty was for 90. Ugh. I knew from reading about them that Harbor Freight was not at all lenient about the warranty period. I figured it was just a loss. And that eventually I might take it apart to see how it worked.

I found several youtube videos describing my problem, and the fix was rather easy. Seems that the transducer comes unglued from the bottom of the pan, and just needs to be re-epoxied on.

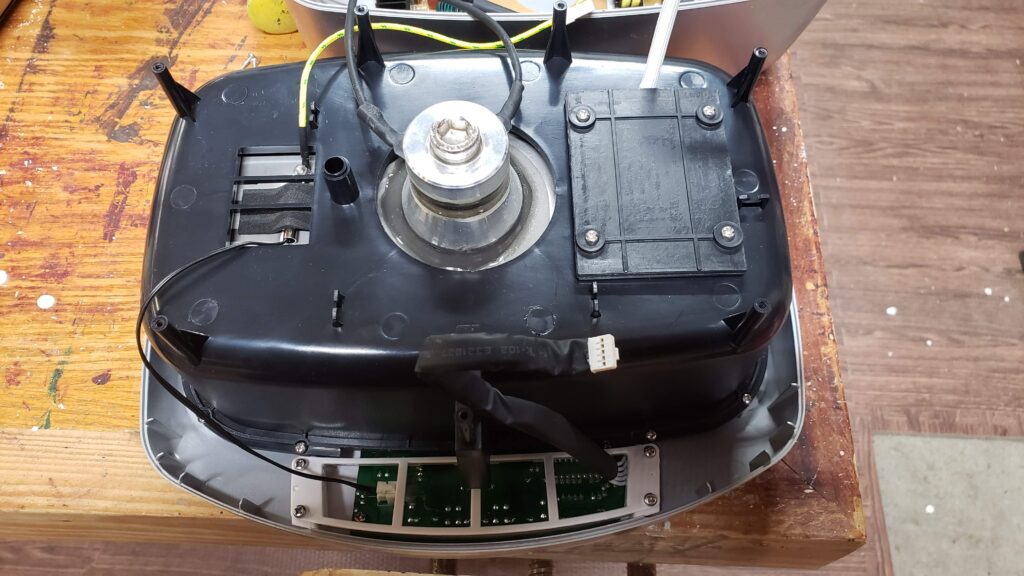

I cleaned it out, flipped it upside down, and took the screws out. After disconnecting some wires from the control board and removing the bottom, I could access the transducer. Sure enough, it had broken free from the pan.

I used some Loctite Heavy Duty epoxy to glue the transducer back on. I first cleaned the pan and transducer as best I could. The layer of epoxy on the transducer was not coming off. I then sanded both surfaces to give a scuffed surface for the epoxy to adhere to.

I applied a generous amount of the well-mixed epoxy to both surfaces, and then put the transducer back on, adjusting it so that it was snug in the pan recess.

One other issue I’ve heard a lot about is the leaking of fluid into the case. This is caused by the poor gasket and gap between the top cover and the pan. As the control board is at the bottom of the case, leaks can run down to it and cause it to short out. From what I’ve read, this will completely render the unit useless.

I took this opportunity to clean both surfaces and apply a good layer of silicone sealant.

Here it is reassembled, before cleaning up the excess.

Let’s check the results:

Thanks for reading! I hope you’ve found this useful.